Post by : Meena Rani

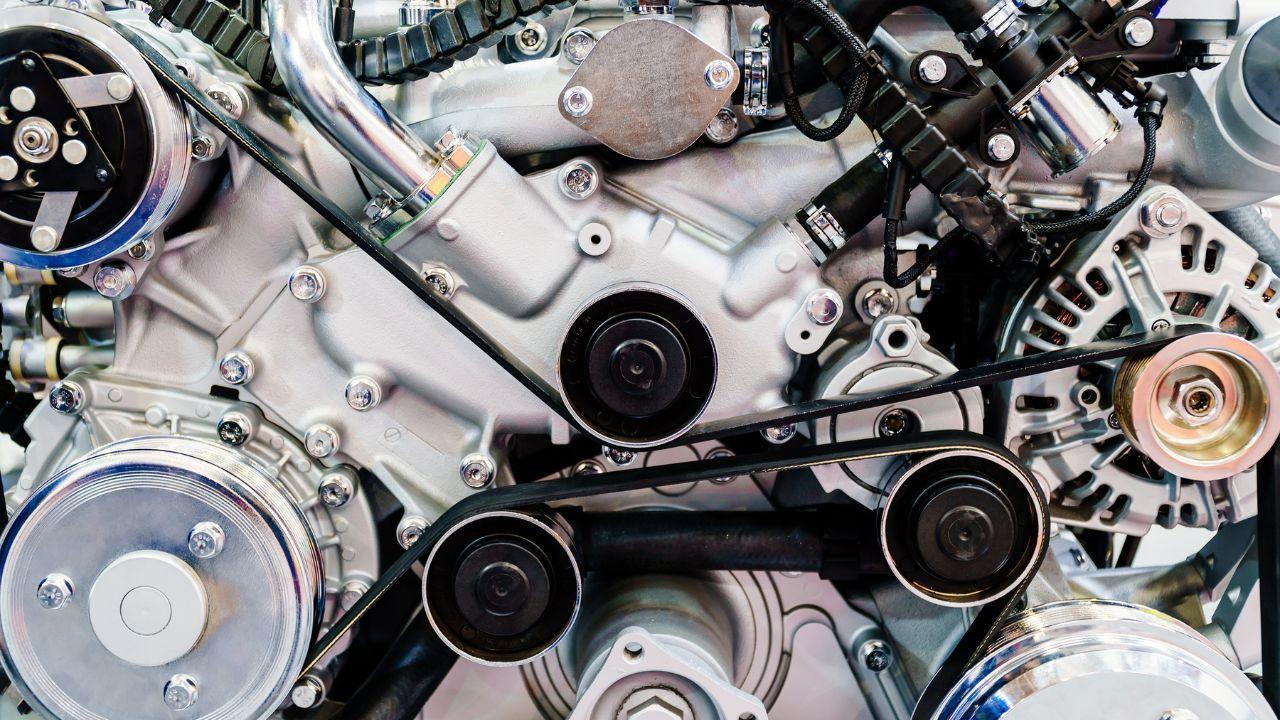

In modern industries, especially in food processing, pharmaceuticals, biotechnology, and cosmetics, maintaining strict hygiene standards is not just important—it is essential. A single lapse in hygiene can lead to severe consequences, including contamination, product recalls, financial losses, and damage to a company’s reputation. The key to ensuring these hygiene standards are met lies in using certified hygienic components in industrial machinery. These components are designed to prevent contamination, are easy to clean, and comply with global hygiene regulations.

Certified hygienic components are manufactured with precision and tested rigorously to meet international standards such as FDA, EHEDG, and ISO 14159. These components play a crucial role in reducing the risk of bacterial growth, preventing cross-contamination, and maintaining the safety and quality of products in critical industries.

Risks of Using Uncertified or Low-Quality Components

Industrial machinery is only as safe as the parts it is built from. Using uncertified or outdated components can result in serious hygiene problems. Components that are poorly designed or made from substandard materials can easily harbor bacteria, corrode quickly, or degrade under cleaning chemicals and high temperatures. This can lead to:

Biofilm Formation: Tiny gaps and crevices in poorly designed components allow bacteria to grow and form biofilms that are difficult to remove.

Cross-Contamination: Contaminated machinery can transfer harmful bacteria or allergens between different batches of products.

Equipment Failures: Corroded or weak parts can malfunction, causing production delays or accidents.

Regulatory Violations: Failure to comply with hygiene standards can lead to penalties, fines, or shutdowns of manufacturing facilities.

Industries dealing with food, medicine, or sensitive cosmetic products cannot afford such risks. Even a minor contamination can cause significant financial and reputational damage.

What Makes Certified Hygienic Components Essential

Certified hygienic components are designed specifically for environments where cleanliness is crucial. These components are manufactured using materials that are safe, durable, and resistant to bacteria. Some examples of hygienic components include:

Stainless steel machine leveling feet for stable and clean equipment setups.

IP67/IP69K waterproof bearing units to prevent water and dust ingress.

EHEDG-certified knobs, handles, and fasteners for sanitary operations.

Sealed caster wheels suitable for cleanroom or food processing environments.

FDA-approved gaskets, seals, and elastomers that contact food or medicines.

These components are engineered to withstand aggressive cleaning chemicals, high temperatures, and frequent washing. Certification ensures that they can resist contamination, are easy to clean, and meet global safety standards.

Key Design Features of Hygienic Components

Certified hygienic components include specific design elements that reduce the risk of contamination:

Rough or porous surfaces can attract bacteria. Certified components are polished to smooth finishes, often with Ra<0.8 µm surface quality. This prevents bacterial adhesion and makes cleaning much easier.

Hygienic components are designed with angles and curves that allow liquids to drain easily. Standing water or cleaning solutions can become breeding grounds for bacteria, so a self-draining design is crucial.

Joints, threads, and small gaps are hotspots for microbial growth. Hygienic components are manufactured with sealed joints, encapsulated fasteners, or non-threaded designs to prevent bacteria from entering these areas.

High-grade stainless steel (such as AISI 316L) is used for resistance to corrosion and compatibility with strong cleaning chemicals. Elastomers used in seals are FDA-approved and designed to withstand high temperatures and harsh cleaning agents without degradation.

Protecting Against Contamination and Product Recalls

Product recalls can be devastating for any company. In food processing or pharmaceutical industries, contamination can spread quickly and impact thousands of products. Certified hygienic components play a critical role in preventing these incidents by:

Ensuring Clean-In-Place (CIP) compatibility, which allows machinery to be cleaned without full disassembly.

Eliminating hidden areas where bacteria or allergens can accumulate.

Reducing manual cleaning efforts also lowers the risk of human error.

Minimizing downtime and maintenance costs due to easier cleaning and longer-lasting components.

Using these components ensures not only safety but also production efficiency, saving time and money in the long run.

Choosing the Right Supplier for Hygienic Components

Selecting the right supplier is as important as choosing the components themselves. Key factors to consider include:

Specialization in hygienic and sanitary components.

Transparent certification and testing processes.

Ability to provide custom components for unique industrial setups.

Quick availability and clear delivery timelines.

Commitment to sustainability and compliance with global regulations.

Reputable suppliers provide comprehensive support, helping industries choose the best components for their specific processes, ensuring long-term operational safety and efficiency.

Building Hygiene Into the Foundation of Industrial Equipment

Hygiene should never be an afterthought. It must be built into the machinery from the start. Every bolt, knob, foot, and bearing should be chosen with hygiene in mind. Certified hygienic components form the foundation of safe and clean operations in critical industries.

These components are not just parts—they are protective tools that safeguard product quality, ensure compliance with regulations, and protect the company’s reputation. Companies that invest in hygienic components demonstrate a commitment to excellence, safety, and customer trust.

In conclusion, certified hygienic components are essential for industries that require clean, safe, and reliable machinery. They reduce contamination risks, prevent costly recalls, and support efficient operations. Choosing the right components and suppliers ensures long-term safety, product quality, and operational success.

Certified hygienic components, industrial machinery parts, contamination control

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi