Post by : Amit

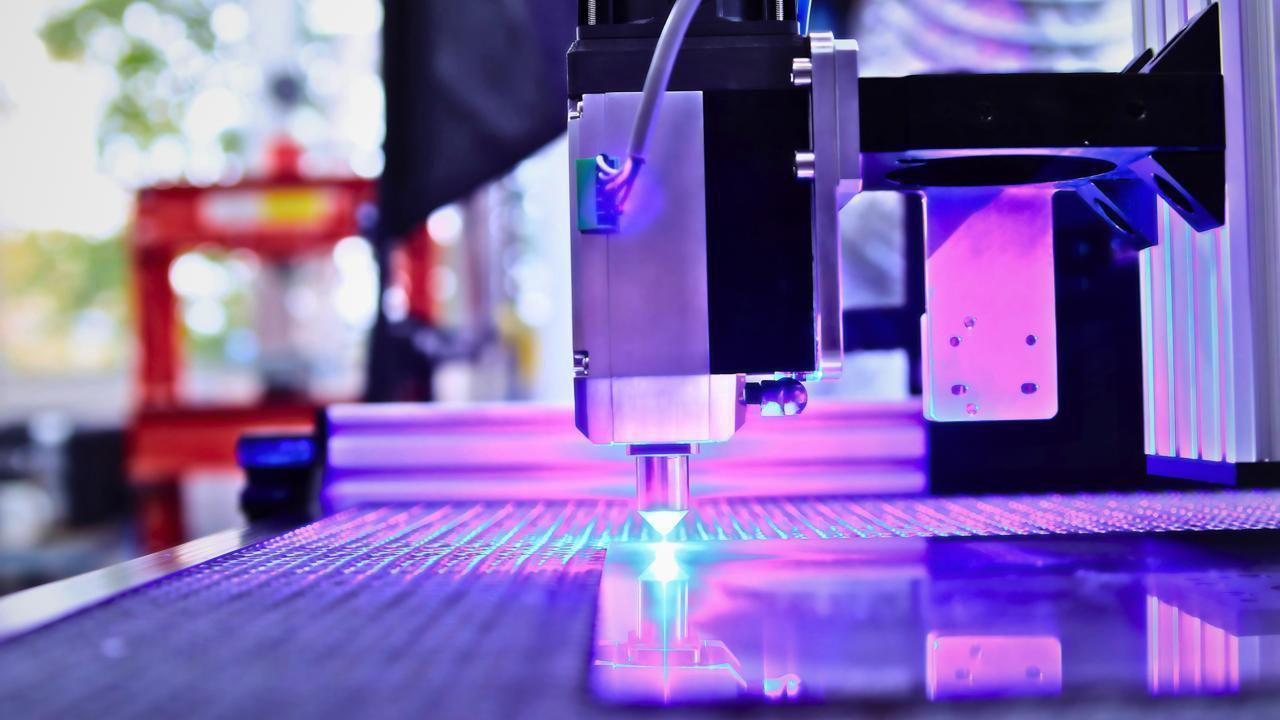

DMG Mori, the German-Japanese powerhouse in CNC technology, has unveiled a new generation of AI-integrated CNC machines capable of autonomously detecting tool wear and coordinating real-time replacement orders — without human input.

The breakthrough, announced at the company’s innovation summit in Tokyo, signals a decisive leap toward fully self-managing machine tools in industrial settings. The AI-driven system is the first in the world to combine real-time predictive diagnostics, automated supply chain integration, and machine learning-based optimization in a standard CNC framework.

Traditionally, CNC machines rely on scheduled maintenance or manual inspection to determine when a tool — such as a drill bit or milling head — needs replacing. This can often result in overuse, sudden failure, or unnecessary downtime.

DMG Mori’s new platform changes the game. Using embedded edge AI sensors, the system monitors vibration, acoustic emissions, torque, and temperature, learning patterns of wear for each specific tooling component. When predictive algorithms determine that a tool is nearing its lifecycle threshold, the machine not only alerts the operator, but automatically triggers a replacement order through a secure API to certified tooling suppliers.

The result is seamless, autonomous maintenance—and a reported 40% reduction in unplanned downtime during industrial trials across Asia and Europe.

Dr. Masaru Tanaka, Chief Innovation Officer at DMG Mori, described the technology as a “closed-loop intelligence system that finally bridges operational AI with industrial reality.” He added:

“Our machines no longer wait to be maintained. They predict, plan, and respond in real time—so factories don’t stop moving.”

The platform doesn’t operate in isolation. DMG Mori has partnered with global tooling suppliers, including Sandvik Coromant, Kennametal, and Mitsubishi Materials, to enable API-based tooling orders. Once a wear event is predicted, the system cross-checks compatible part inventories, selects a preferred vendor, and places the order—all within milliseconds.

In smart factory environments, this innovation is expected to unlock massive productivity gains. During the pilot at an aerospace parts facility in Nagoya, the system reduced total tooling downtime from 12 hours per week to under 3 hours, while improving part accuracy by reducing micro-wear drift.

The machines also use machine learning to optimize cutting parameters on the fly, balancing speed, surface finish, and energy efficiency depending on the operation.

This development positions DMG Mori at the forefront of the Industry 4.0 movement, where AI is no longer just a software layer, but a built-in function of the equipment itself. Rather than add-on solutions or cloud-reliant apps, the company’s new CNC machines come with onboard edge computing, allowing them to make critical decisions even in low-connectivity environments.

Industry analysts suggest the innovation will appeal especially to high-mix, high-precision sectors like aerospace, medical device machining, and electric vehicle parts, where tool life and quality consistency are paramount.

With manufacturing becoming increasingly digital, real-time, and globally synchronized, DMG Mori’s smart CNC machines represent a new class of intelligent industrial automation—self-aware, self-correcting, and seamlessly networked.

By embedding AI directly into the metal-cutting heart of production, DMG Mori isn’t just refining the CNC process — it’s redefining the relationship between human and machine. Operators move from hands-on tool changers to strategic overseers. Maintenance becomes proactive, not reactive. And factories inch closer to lights-out, fully automated operations.

In a world where downtime costs millions, DMG Mori’s innovation doesn’t just save time—it rewrites the rules of what smart manufacturing looks like.

German, Japanese, CNC technology

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi