Post by : Amit

Lear’s New Modular Wiring Platform Redefines EV Architecture

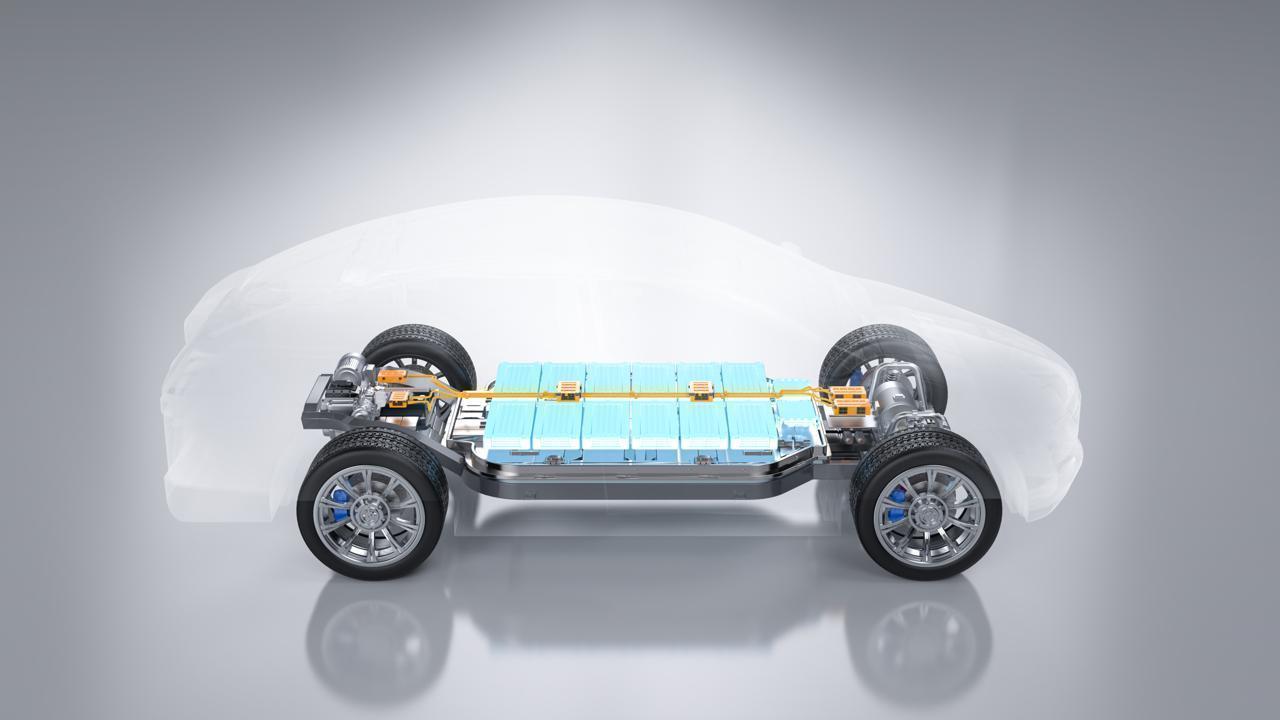

In a bold move set to reshape the electric vehicle supply chain, Lear Corporation has unveiled a next-generation modular wiring system built specifically for EV skateboard platforms. The announcement, which underscores Lear’s deepening commitment to EV innovation, promises a lighter, smarter, and highly scalable solution for automakers navigating the complexities of electric vehicle architecture.

In today’s electric vehicle market, skateboard platforms—flat, chassis-integrated systems housing the battery, motors, and essential components—are becoming the standard. But wiring these platforms efficiently, safely, and affordably has been one of the lingering engineering puzzles. Lear’s new modular system aims to solve that puzzle with an integrated approach designed to support automation, reduce weight, simplify manufacturing, and future-proof vehicles for over-the-air (OTA) evolution.

The Need for Modular, Scalable Wiring in EVs

As EVs proliferate, automakers are racing to optimize vehicle design for performance, efficiency, and manufacturability. The skateboard chassis allows for a uniform, flat design that accommodates a wide variety of vehicle types—from compact crossovers to full-size trucks. But this versatility demands equally adaptable subsystems—including wiring.

Traditional wiring harnesses, typically custom-built for each vehicle model, are bulky, labor-intensive to install, and hard to adapt across platforms. In contrast, Lear’s modular wiring platform introduces standardized, repeatable modules that can be configured across multiple vehicle types with minimal redesign.

"EV architecture is rapidly evolving," says Ray Scott, CEO of Lear Corporation. "What we’re introducing is not just a harness—it’s a flexible, plug-and-play system that’s engineered to evolve with vehicle platforms as they become more software-defined and electrified."

How the System Works: Modules, Nodes, and Intelligence

Lear’s new modular wiring system breaks from tradition by moving away from a single massive wiring harness. Instead, the solution comprises discrete wiring modules designed to plug into functional nodes located throughout the skateboard platform. These nodes act as data and power hubs, communicating across the vehicle’s electronic control units (ECUs).

The architecture is composed of:

This modularity introduces significant gains in production speed and design flexibility. If a manufacturer wants to develop a sedan and SUV on the same skateboard, only a few modules need to change—reducing design cycle time and manufacturing complexity.

Manufacturing Efficiency Meets Sustainability

The environmental impact of EV production is under growing scrutiny. With sustainability baked into its design, Lear’s modular system supports automated production lines and reduces material waste. Shorter cable lengths, fewer connectors, and lightweight shielding all contribute to:

This is a win-win for automakers. Reduced material usage means lower cost and better sustainability credentials. Faster install time cuts labor hours, aligning well with high-throughput gigafactory ambitions.

Enabling OTA Updates and ADAS Scalability

Another standout feature is the system’s readiness for software-defined vehicles (SDVs). Many OEMs are moving toward platforms that can be updated over-the-air, evolving over time with new features, bug fixes, and performance enhancements. This requires a robust, flexible electrical backbone—something Lear’s solution provides.

Its intelligent wiring nodes can dynamically route data, prioritize bandwidth for autonomous driving systems, and scale sensor integration as ADAS (Advanced Driver Assistance Systems) evolve. This means that as a vehicle ages, new features can be added without retrofitting core wiring—a huge advantage for automakers seeking long-term customer engagement and upgradable product ecosystems.

"This system supports the future of vehicle digitalization," says Katiyama Kobayashi, Lear’s Senior Director of Product Innovation. "From enhanced driver assistance to data-heavy AI inference, our wiring architecture is ready to support vehicles for a 15-year software lifecycle."

Industry Collaboration and Tier-1 Momentum

Lear is not just designing in a vacuum. The company has developed this system in collaboration with multiple Tier-1 and Tier-2 suppliers, sensor manufacturers, and EV startups. By ensuring interoperability and automotive-grade robustness, Lear’s wiring modules are certified for thermal extremes, vibration loads, and EMI resistance across geographies.

Automakers ranging from Detroit to Munich are already evaluating the system. According to internal sources, Lear’s platform is under advanced integration review by two major OEMs and one EV-only manufacturer for 2026 and 2027 model years.

The modular wiring system also aligns with automotive megatrends—including zonal architecture, vehicle electrification, and advanced connectivity—which are reshaping how Tier-1 suppliers like Lear participate in the value chain.

A Look Under the Hood: Materials and Specs

The technical backbone of Lear’s modular platform is built using:

These choices were not just made for performance—they also anticipate emerging regulatory standards for EV fire safety, modular validation, and repair traceability. The embedded chips, for example, can flag short circuits, corrosion, or thermal events long before they pose a hazard.

Solving Pain Points in the Supply Chain

EV startups and legacy OEMs alike face mounting pressure from supply chain fragility and inflationary costs. Custom wiring systems are often one of the biggest bottlenecks, with design iterations taking months and unexpected supplier delays wreaking havoc on production schedules.

Lear’s standardized modularity offers a compelling solution. Instead of waiting weeks for a bespoke wiring harness, OEMs can select from a pre-certified module library, streamlining validation and procurement. This also allows them to pivot quickly between vehicle variants or change suppliers without scrapping entire system designs.

Moreover, since Lear has already optimized these modules for robotic assembly, gigafactories can scale up rapidly without retraining labor or retooling production lines.

The Competitive Landscape: Who Else Is Playing Catch-Up?

While Lear takes the lead, others are not far behind. Yazaki, Aptiv, and Sumitomo are all developing next-gen harness systems, but Lear’s edge lies in its high production readiness and deep integration with software platforms. Its ability to integrate seamlessly into zonal architectures and feed diagnostic data into cloud-based platforms gives it an edge in the software-defined EV race.

Industry insiders believe Lear’s wiring solution could become the industry reference design by 2027—especially for new entrants looking to bypass the complexity of legacy vehicle engineering.

What This Means for the Future of EV Manufacturing

Lear’s debut is more than just a product launch—it's a signal of how vehicle electronics will be structured in the next decade. Gone are the days of spaghetti-style harnesses and rigid one-off designs. As electric and autonomous vehicles become platform-driven and data-rich, wiring systems must become modular, intelligent, and agile.

By delivering a wiring solution that checks all these boxes, Lear has positioned itself at the heart of next-gen EV production.

A Quiet Revolution Underneath Your Feet

You won’t see Lear’s new modular wiring system from the driver’s seat—but it may be one of the most important EV upgrades happening today. By reimagining the way vehicles are wired, the company is enabling faster innovation, better reliability, and smarter vehicles from the ground up.

And in the world of EVs, where every gram, volt, and second counts, smart wiring might just be the secret weapon automakers have been waiting for.

EV Battery

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi