Post by : Avinab Raana

Farasis Energy, backed by Mercedes, is moving its solid-state EV battery technology from lab to road. In a recent investor update, the company confirmed it will begin delivering its sulfide-based all-solid-state batteries by the end of 2025. The timing makes this one of the earliest solid-state EV battery roll-outs to hit real production.

Solid-state batteries replace—or greatly reduce—the liquid electrolytes used in conventional lithium-ion batteries. With sulfide-based solid electrolytes, the promise is higher energy density, faster charging times, improved safety, and longer lifespan. Farasis claims its first-generation solid-state pack can reach 400-500 Wh/kg, a major leap over most today’s EV batteries.

To get there, Farasis is building a 0.2 GWh pilot production line dedicated to solid-state output. Early deliveries will be small batches sent to select customers, serving as a testbed for manufacturing refinement and real-world feedback. It’s a critical learning phase, transitioning from research prototypes to vehicles people will actually buy and drive.

Farasis isn’t stopping with the first version. The second generation, expected in 2026, promises to push energy density further—still using sulfide chemistries but refined such that performance and durability improve. By 2027, the third generation is targeted to move “over 500 Wh/kg” in energy density. If achieved, that would put Farasis among the top in the battery arms race.

One of the biggest concerns with solid-state technology is cost. Farasis reports its “semi-solid-state” batteries today only cost about 5-10% more than traditional liquid-electrolyte batteries. That margin is critical: if solid-state EV batteries remain wildly more expensive, adoption will be limited. But this modest extra cost suggests an accelerated path toward broader EV offerings that can compete on price as well as performance.

Mercedes has had a stake in Farasis since 2020, positioning itself to gain early access to cutting-edge battery tech for its luxury EVs. The EV race is increasingly about battery innovation, who can pack more kWh, charge faster, and maintain performance over many cycles. Farasis’ progress could force other OEMs to accelerate their own solid-state plans.

With solid-state tech, range improvements are expected to be substantial. If Farasis’ claims hold, vehicles could travel further on single charges, and charging could be faster without the overheating or degradation problems plaguing some lithium-ion systems. The promise also includes longer battery life—more full charge/discharge cycles before performance drops significantly. These aren’t incremental upgrades; they are foundational. For drivers, it means fewer range anxieties, fewer battery replacements, and charging infrastructure might stretch further between stations.

Despite the excitement, several hurdles remain. Solid‐state batteries are harder to manufacture at scale. Scaling from pilot line to gigawatt-hour facilities means mastering new materials, ensuring consistency, and controlling manufacturing costs. Reliability under harsh real-world conditions (extreme heat, cold, vibration) still needs extensive validation. Safety, especially in case of damage or crash, must match or exceed current standards.

Even if Farasis begins limited deliveries in 2025, widespread adoption will take longer. Automakers will need to test durability in vehicle platforms, supply chains must ramp up, charging networks must adapt, and customers need to be convinced the premium is worth it. Early models may be luxury or high-end as cost comes down. Over time, solid-state tech can move into mainstream EVs, if Farasis and its partners nail production scale and quality control.

If Farasis meets its 2025 target, it could shift the competitive dynamics among battery suppliers, EV makers, and even energy policy. Companies that were slow with solid-state development may find themselves pressured to catch up. EV buyers might expect higher energy density and faster charging as standard features. Infrastructure planners may consider grids, charging‐stations, and end-of‐life battery recycling with solid-state capabilities in mind.

Keep an eye on a few things: earliest deliveries and how they perform in real world; updates from Farasis about full-scale manufacturing; announcements from vehicle makers planning to integrate these batteries; how pricing evolves; and safety and lifecycle data. These are the metrics that will tell whether solid-state EV batteries really deliver on their promise, or remain a powerful but narrowly commercial idea.

The acceleration of solid-state EV battery timelines suggests the EV revolution is entering its next phase. No longer is it just about “can we make EVs”; now the question becomes “how far, how fast, and how durable can they get.” If Farasis Energy succeeds in delivering safe, affordable, high‐density solid-state batteries by end‐2025, it won’t just be a technological win. It will be a signal that the next leap in EV performance is here and that the future drivers want is coming into view.

#trending #latest,#SolidStateBattery #EVTech #FarasisEnergy #Mercedes #ElectricVehicles #BatteryInnovation #GreenTransport #NextGenEV

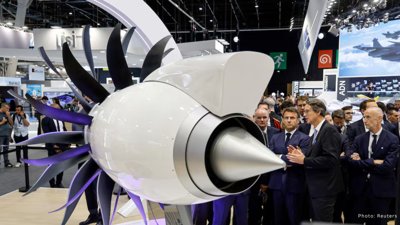

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi