Post by : Meena Rani

The Airbus A321XLR, with its extended range and growing demand, relies heavily on the Pratt & Whitney PW1100G engine. While the aircraft’s design and market appeal are strong, production constraints at the engine level present significant bottlenecks, impacting delivery schedules and Airbus’s ramp-up targets.

The PW1100G, part of Pratt & Whitney’s Geared Turbofan (GTF) family, offers fuel efficiency, reduced emissions, and noise reduction. Its advanced technology makes it the engine of choice for the A321XLR, enabling airlines to operate longer routes with better economics.

Despite its advantages, the PW1100G engine has faced production delays due to multiple factors. These bottlenecks affect Airbus’s ability to meet delivery targets for the A321XLR and other A320 family aircraft.

The GTF engine incorporates cutting-edge materials, precision gearboxes, and advanced fan blade designs. Manufacturing tolerances are extremely tight, requiring meticulous quality checks and skilled labor. Any disruption in production can cause cascading delays downstream.

Components sourced from Tier-2 and Tier-3 suppliers are critical. Delays in specialty alloys, high-temperature components, or electronic controls can halt assembly lines. Global supply chain pressures, including transportation bottlenecks and material shortages, exacerbate the problem.

GTF engines require rigorous testing to meet safety and performance standards. Even minor defects detected during quality checks can delay engine delivery, affecting aircraft assembly schedules and airline commitments.

Engine shortages directly influence Airbus’s production pace. Airlines awaiting A321XLR deliveries face extended timelines, which can impact route planning, fleet expansion, and financial projections.

Airbus and Pratt & Whitney have implemented several measures to minimize the impact of engine bottlenecks:

Pratt & Whitney works closely with suppliers to streamline processes and reduce bottlenecks. By using AI and digital tracking systems, they can anticipate delays, reroute components, and maintain assembly line continuity.

Both Airbus and Pratt & Whitney recognize the need for long-term solutions to prevent recurring engine bottlenecks. Investments focus on automation, workforce expansion, and technological upgrades in engine manufacturing.

Robotics and automated inspection systems are being introduced in engine assembly. These technologies increase precision, reduce human error, and allow for higher throughput without compromising quality.

Skilled labor is critical for complex engine assembly. Training programs and knowledge transfer initiatives help build capacity and ensure that production targets can be met consistently.

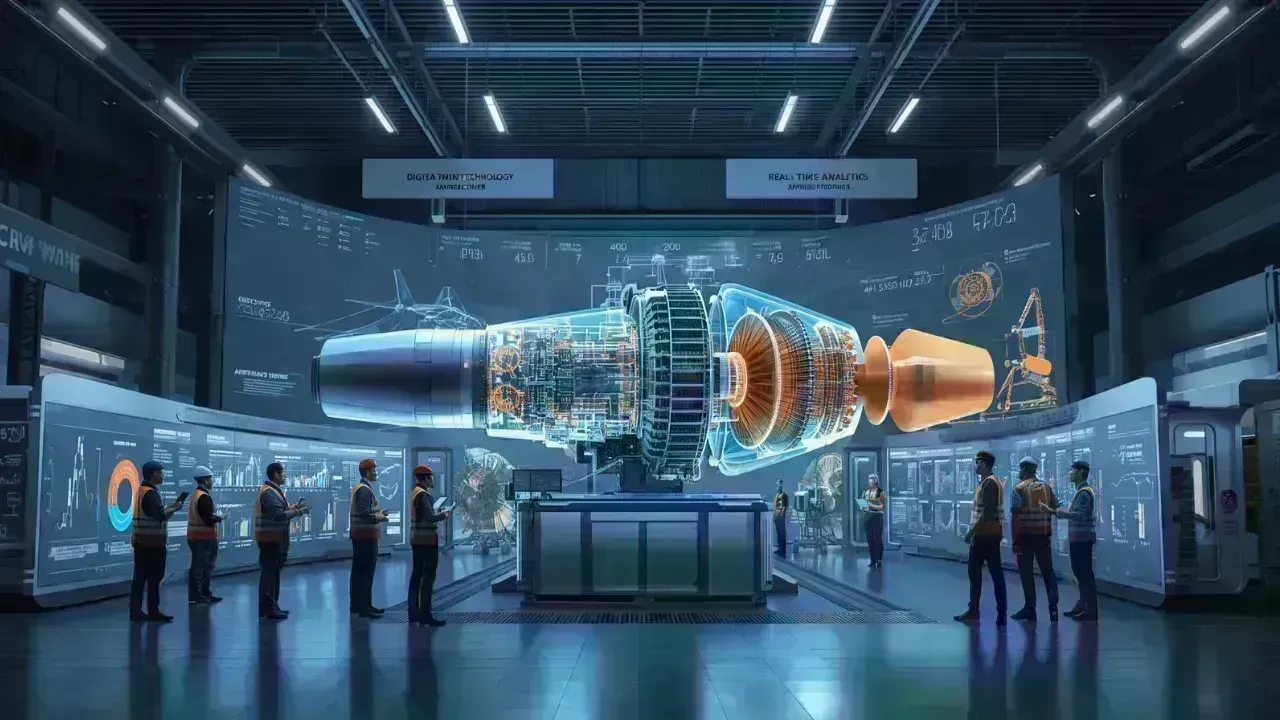

Digital twin models simulate engine assembly and performance, allowing engineers to detect potential issues before physical production. Predictive analytics help prioritize resources and anticipate delays across the supply chain.

The PW1100G has faced similar issues during the A320neo program’s early ramp-up. Lessons learned include:

Implementing these lessons ensures smoother production for the A321XLR and future aircraft programs.

Engine bottlenecks can influence airline purchasing decisions. Timely deliveries build confidence in Airbus and its partners, while delays may encourage airlines to consider competitors or adjust fleet expansion plans.

Rivals like Boeing monitor Airbus’s engine supply issues closely. Efficient resolution of PW1100G bottlenecks is crucial to maintaining market leadership in narrow-body long-range aircraft.

Airbus and Pratt & Whitney maintain close communication with airline customers to manage expectations, provide delivery updates, and offer compensation or support when delays occur.

As Airbus scales A321XLR production, resolving engine bottlenecks is essential. Investments in manufacturing capacity, digital technologies, and supplier collaboration are expected to mitigate delays and support reliable delivery schedules.

With the ramp-up plan in place, Pratt & Whitney aims to match engine production with Airbus assembly rates, ensuring timely delivery of aircraft without sacrificing quality or safety.

Continuous improvement in the PW1100G design enhances reliability, maintainability, and performance, supporting Airbus’s long-term growth strategy.

In conclusion, while engine bottlenecks present a significant challenge for A321XLR deliveries, proactive collaboration, investment in technology, and digital solutions allow Airbus and Pratt & Whitney to minimize impact. Successfully addressing these bottlenecks is critical for maintaining Airbus’s production ramp-up, airline satisfaction, and competitive advantage in the narrow-body aircraft market.

#PW1100GEgine #PrattWhitney #A321XLR #EngineBottleneck #AirbusProduction #GearedTurbofan #AerospaceSupplyChain

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi

Canada Post Workers Strike Halts Nationwide Mail and Parcel Services

Canada Post halts operations as CUPW strike disrupts mail and parcel delivery nationwide amid disput

PM Modi Launches BSNL ‘Swadeshi’ 4G Network, 97,500 Towers Built

India enters global telecom league as PM Modi inaugurates BSNL’s indigenous 4G, connecting 26,700 vi

India’s Iconic MiG‑21 Takes Final Flight After Six Decades of Service

After 60 years India retires its MiG‑21 fighter jet, a legendary yet controversial warplane marking

Hindustan Zinc unveils AI hotspot monitoring at Debari smelter

Hindustan Zinc launches AI-powered Switchyard Hotspot Monitoring at Debari smelter to cut outages bo

Chinese experts worked inside sanctioned Russian drone plant

Chinese drone specialists visited IEMZ Kupol supplying parts and drones via intermediaries, deepenin