Post by : Meena Rani

What if we could design materials that bend light backward, absorb sound perfectly, or become stronger when stretched? For centuries, materials have been discovered — not invented. But with the rise of metamaterials, scientists are flipping that notion entirely.

Metamaterials are engineered structures that derive their unique properties not from their composition, but from their internal architecture — patterns smaller than the wavelength of light, sound, or mechanical waves they interact with.

By precisely designing these architectures, scientists can manipulate electromagnetic, acoustic, and mechanical waves in ways that natural materials cannot. The result: invisibility cloaks, ultra-efficient antennas, shock-absorbing armor, and programmable materials that adapt to their surroundings.

Among their many variants, mechanical metamaterials — those designed to manipulate mechanical stress, strain, and motion — are particularly reshaping engineering, architecture, and robotics.

In short, metamaterials mark a paradigm shift from discovering new substances to designing new realities.

The term metamaterial comes from the Greek meta, meaning “beyond.” These materials go beyond the limitations of nature, offering properties unattainable in conventional substances.

Metamaterials are composed of repeating units or cells — called “meta-atoms” — that are engineered to interact with waves or forces in specific ways. The overall behavior of the material depends on the geometry, size, and arrangement of these units rather than their chemical makeup.

For example, a metamaterial made from simple metals or plastics can bend light, sound, or vibrations in ways that defy physics as we know it — because of how those elements are arranged.

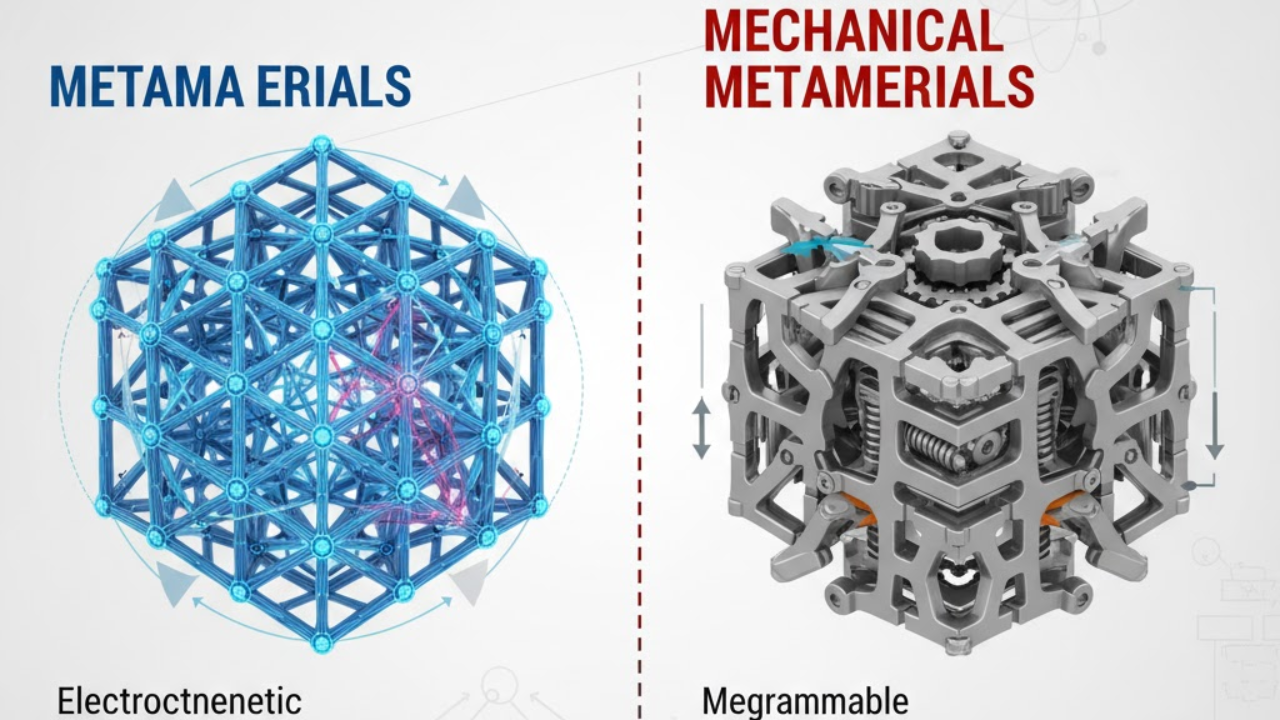

Metamaterials exist in several domains:

Electromagnetic Metamaterials: Control light, microwaves, or radio waves.

Acoustic Metamaterials: Manipulate sound and vibration.

Mechanical Metamaterials: Shape stress, strain, and mechanical response.

Thermal Metamaterials: Direct or insulate heat flow in programmable ways.

Each category opens up revolutionary applications across science, defense, communication, and construction.

Metamaterials achieve their extraordinary properties through structural design at subwavelength scales.

Traditional materials respond to waves according to their atomic structure. Metamaterials, on the other hand, use geometric patterns that resonate with those waves. By controlling how waves propagate through or reflect off these patterns, engineers can design materials with properties never seen before — such as negative refractive index or acoustic cloaking.

In other words, metamaterials do not break the laws of physics — they rewrite the boundary conditions of how physics behaves inside them.

One of the first major breakthroughs in metamaterials was the creation of a material with a negative index of refraction.

Normally, when light enters a material, it bends (refracts) in a predictable direction. But in metamaterials designed with negative refractive indices, light bends the opposite way — a phenomenon impossible in natural materials.

This property opened the door to revolutionary applications like:

Superlenses that overcome diffraction limits, allowing imaging smaller than the wavelength of light.

Invisibility cloaks that guide light around an object, rendering it undetectable.

Compact antennas for faster, more efficient communication systems.

Negative index metamaterials became the foundation for modern photonic and electromagnetic metamaterial research.

While electromagnetic metamaterials manipulate light, mechanical metamaterials manipulate forces and motion.

They are designed to exhibit unusual responses to mechanical stimuli — such as compression, tension, or torsion — by structuring matter in intricate patterns. These materials can twist, fold, or deform in counterintuitive ways while maintaining stability.

Key examples include:

Auxetic materials that expand laterally when stretched (opposite of normal materials).

Origami-inspired materials that fold or unfold predictably for adaptive structures.

Programmable lattices that can change stiffness or shape on demand.

Such systems are inspiring a new generation of adaptive architectures, wearable robotics, and smart prosthetics that mimic living tissue or biological adaptability.

Auxetic materials have a negative Poisson’s ratio, meaning they expand perpendicularly when stretched — unlike conventional materials that contract.

This makes them exceptionally resistant to indentation and fracture. Applications include:

Impact-resistant helmets and armor.

Medical implants that conform better to tissue.

Flexible, energy-absorbing foams.

Inspired by the Japanese arts of folding and cutting, these designs create materials that can reconfigure shape, stiffness, or volume dynamically.

Such structures are ideal for:

Space-deployable structures like solar panels.

Soft robotics that mimic organic movement.

Architectural facades that adjust for light and ventilation.

By creating intricate 3D networks of repeating unit cells, engineers can produce ultra-light yet strong materials — stronger than steel but lighter than plastic.

Applications span aerospace, automotive, and biomedical implants.

These materials integrate sensors, actuators, or responsive polymers that change shape, stiffness, or orientation in response to external stimuli like heat, magnetism, or pressure.

They serve as the building blocks of intelligent materials capable of self-adjustment or self-repair.

Mechanical metamaterials have also revolutionized acoustic engineering.

By structuring materials at scales smaller than the wavelength of sound, researchers can create acoustic metamaterials that:

Block specific sound frequencies.

Channel vibrations harmlessly away from sensitive components.

Create “quiet zones” by redirecting noise around obstacles.

These materials are being integrated into noise-canceling walls, soundproof aircraft cabins, and even stealth submarines that absorb sonar waves.

In mechanical systems, metamaterials can isolate vibrations from machinery, improving performance and longevity.

Beyond mechanical applications, optical metamaterials are reshaping the field of photonics — controlling how light behaves at nanoscale levels.

Applications include:

Metasurfaces: Ultra-thin coatings that control light reflection, absorption, and phase at subwavelength precision.

Flat lenses (metalenses): Replacing bulky glass optics with nanostructured layers that focus light perfectly.

Optical cloaking: Directing electromagnetic waves around objects to hide them from detection.

Photonic computing: Using light-based circuits for ultrafast, energy-efficient computation.

These developments are leading toward miniaturized optical systems, from AR/VR displays to quantum communication devices.

Mechanical metamaterials can also be designed to absorb impact energy intelligently.

Through hierarchical lattice structures or reentrant geometries, they dissipate energy under compression while maintaining strength — perfect for crash protection, protective gear, and aerospace impact shields.

These energy-absorbing materials outperform traditional foams and composites, offering lightweight yet robust protection.

Modern research is merging metamaterials with artificial intelligence, sensing systems, and robotics, giving rise to intelligent materials capable of real-time adaptability.

For example:

AI algorithms optimize lattice structures for desired mechanical or acoustic responses.

Embedded sensors enable metamaterials to “feel” and adjust under load.

Responsive actuators allow them to morph or stiffen autonomously.

Such AI-driven metamaterials could lead to self-healing infrastructure, robotic skins, and adaptive aerospace surfaces that optimize aerodynamics mid-flight.

The biggest challenge with metamaterials lies in fabrication. Their micro- and nano-scale architectures require advanced manufacturing technologies.

Recent breakthroughs include:

3D and 4D Printing: Additive manufacturing allows precise control over internal geometry, enabling rapid prototyping of complex metamaterial structures.

Microfabrication and Lithography: Used for photonic and electronic metamaterials requiring nanoscale accuracy.

Self-Assembly Techniques: Nano-patterned materials that organize themselves into functional architectures, inspired by biological systems.

4D printing adds the dimension of time — producing structures that evolve shape or properties under external stimuli like temperature or light.

Together, these technologies make metamaterials not just feasible, but scalable.

Metamaterials could redefine sustainability by enabling lighter, stronger, and more efficient designs across industries.

In construction, mechanical metamaterials could reduce the amount of raw material needed for load-bearing structures while enhancing strength and flexibility.

In energy systems, metamaterial coatings can harvest light, heat, or vibration energy to power devices.

By replacing bulky systems with multifunctional smart materials, engineers can design structures that are eco-efficient, adaptive, and long-lasting — a major step toward sustainable engineering.

Despite remarkable progress, several challenges remain in the large-scale adoption of metamaterials:

Complex Manufacturing: Scaling nanoscale designs for mass production is technically demanding and costly.

Durability: Some designs are mechanically fragile under real-world stress.

Material Limitations: Combining functional nanostructures with industrially viable materials requires further innovation.

Design Complexity: Advanced computational tools and AI models are needed to optimize multi-parameter designs.

Researchers are exploring bio-inspired architectures, multi-material composites, and AI-assisted design automation to overcome these limitations.

The future of metamaterials lies in convergence — combining mechanical, photonic, thermal, and electronic functionalities into single, programmable platforms.

By 2035, metamaterials could be the foundation for:

Self-shaping aerospace structures that adjust during flight.

Adaptive buildings that regulate heat, sound, and stress autonomously.

Invisibility systems for defense and communications.

Soft robots with tunable stiffness and motion control.

Wearable protective exoskeletons that absorb shocks dynamically.

The fusion of metamaterials, AI, and advanced manufacturing will blur the line between structure and function — creating materials that are not just strong or light, but intelligent and responsive.

Metamaterials are engineered structures with properties derived from geometry, not composition.

Mechanical metamaterials manipulate stress, strain, and vibration for adaptive performance.

Applications include optics, acoustics, robotics, and impact protection.

Auxetic, origami, and lattice designs lead to unprecedented material behaviors.

Manufacturing advances like 3D/4D printing are enabling scalability.

The integration of AI and nanotechnology will define the next era of intelligent materials.

This article is for informational purposes only. Research on metamaterials and mechanical metamaterials is rapidly evolving, and performance outcomes vary by design, scale, and application. Readers should consult peer-reviewed studies or domain experts before using or investing in metamaterial technologies.

metamaterials, mechanical metamaterials, negative index materials, acoustic materials, photonic structures, architected materials, auxetic design, smart materials, adaptive materials, nanostructured engineering

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi