Post by : Meena Rani

Metal has been the backbone of civilization — from the Bronze Age to the era of aerospace and quantum technology. Yet, even after millennia of refining, casting, and alloying, the methods of shaping metals have remained largely dependent on melting and solidification.

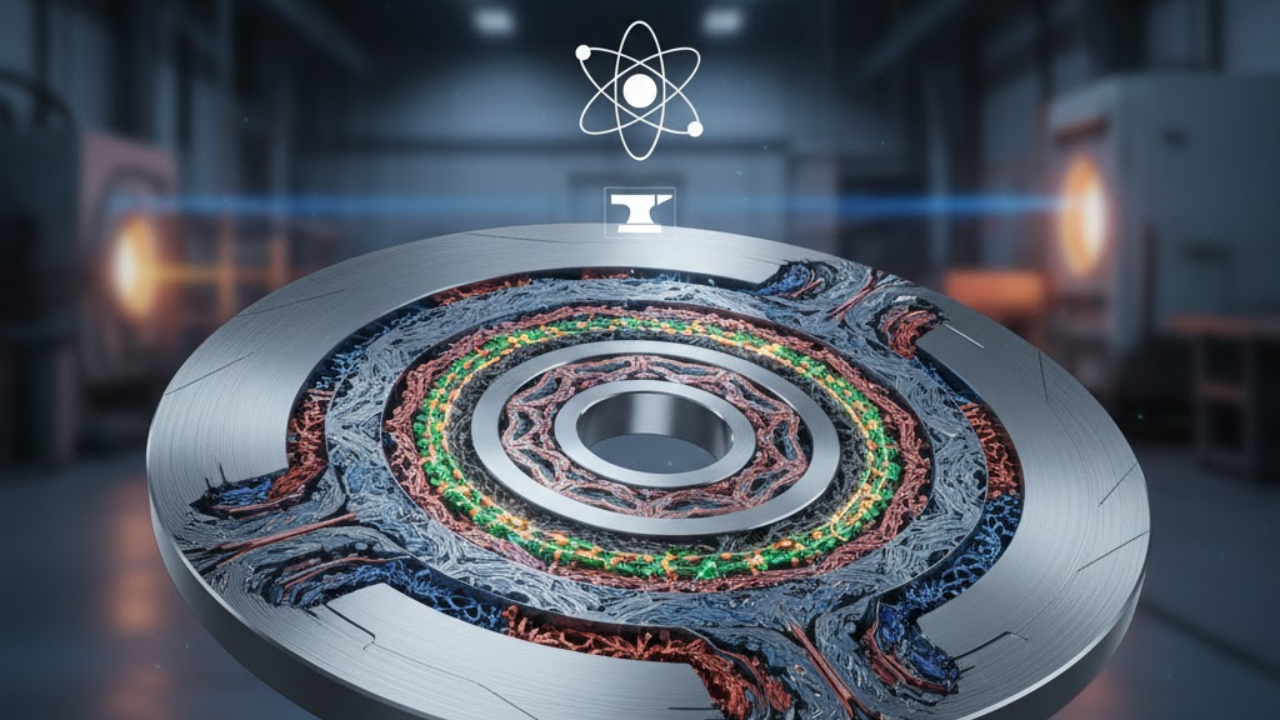

But as technology advances, traditional melting-based metallurgy reaches its limits. High temperatures consume massive energy, cause impurities, and restrict material design. Enter a transformative approach: solid-state metallurgy — a branch of materials science that enables the production and joining of metals without melting.

This innovation is redefining how advanced metal alloys are made, offering unprecedented control over composition, structure, and properties. Solid-state metallurgy has become a cornerstone for lightweight aerospace alloys, next-gen automotive parts, and sustainable metal production, shaping the industrial landscape of the 21st century.

Solid-state metallurgy refers to metal processing methods that occur below the melting point of the materials involved. Instead of melting and recasting, metals are bonded, formed, or sintered in their solid phase through atomic diffusion and pressure.

This approach preserves purity, reduces grain coarsening, and allows precise microstructural control — resulting in stronger, lighter, and more reliable materials.

The idea is simple but revolutionary:

Instead of turning metals into liquid and then cooling them back into shape, why not engineer them directly in their solid state?

This paradigm shift has enabled the rise of ultra-strong alloys, nanostructured metals, and hybrid materials that outperform conventionally cast metals in strength, corrosion resistance, and fatigue life.

The industrial world is demanding materials that are:

Stronger yet lighter,

More sustainable,

Energy-efficient to produce, and

Tailored for extreme environments like space, defense, and nuclear applications.

Traditional metallurgy — involving melting, casting, and forging — often introduces defects such as porosity, segregation, and oxidation. These limit performance and reliability.

Solid-state metallurgy eliminates many of these issues by processing metals below their melting temperatures, allowing atomic-level bonding without melting-related degradation.

Key benefits include:

Reduced energy consumption.

Cleaner, defect-free structures.

Enhanced mechanical properties.

Compatibility with difficult-to-cast metals and composites.

Lower carbon footprint in metal production.

In short, solid-state metallurgy delivers the performance of exotic alloys with the efficiency of sustainable manufacturing.

The field relies on several key physical mechanisms that occur in solid metals:

Atoms migrate across interfaces under heat and pressure, forming strong metallurgical bonds.

When pressure is applied, crystal structures deform, allowing interatomic contact and bonding.

New, defect-free grains form during processing, improving ductility and mechanical integrity.

Controlled heating can rearrange atomic structures into more stable or functional configurations without melting.

Together, these mechanisms allow metals to be joined, sintered, or consolidated at lower temperatures while achieving superior microstructural precision.

Powder metallurgy involves compacting metal powders under pressure and heating them below their melting point — a process called sintering.

This technique allows precise control over composition and produces near-net-shape components with minimal waste.

Modern powder metallurgy supports complex materials like:

Titanium and aluminum alloys for aerospace,

Tungsten and molybdenum for high-temperature tools,

Metal-matrix composites, and

High-entropy alloys with multiple principal elements.

The fine-grained microstructures achieved through powder metallurgy offer exceptional strength-to-weight ratios and fatigue resistance.

Diffusion bonding joins two metal surfaces through atomic diffusion under high pressure and temperature — but below melting.

It creates metallurgical bonds as strong as the parent metal, without using filler materials or fusion welds.

This method is ideal for:

Aerospace turbine blades,

Fuel cell plates,

Heat exchangers, and

Electronic devices.

Diffusion bonding is particularly valuable for joining dissimilar materials, such as titanium and stainless steel, without forming brittle intermetallic layers common in welding.

Friction stir technology uses a rotating tool that softens and stirs metal without melting it. The result is a fine-grained, defect-free joint.

Applications include:

Aircraft fuselage panels,

Railway carriages,

Ship hulls, and

Electric vehicle battery enclosures.

Because it operates in the solid state, friction stir welding avoids issues like porosity, hot cracking, and distortion — offering stronger and safer joints for critical structures.

Spark plasma sintering is a high-speed consolidation process that uses pulsed electric currents and pressure to densify metal powders rapidly.

It’s particularly effective for:

Nanostructured alloys,

Superhard materials,

Tungsten-carbide tools, and

Thermoelectric components.

By shortening sintering time to mere minutes, SPS preserves fine microstructures and reduces energy use — making it one of the most sustainable solid-state processes.

Unlike traditional 3D printing that melts metal powder layer by layer, solid-state additive manufacturing uses cold spray or ultrasonic techniques to deposit material in the solid phase.

These processes produce dense, high-strength components without the residual stress or oxidation typical of melt-based additive manufacturing.

They are being adopted for aerospace parts repair, defense components, and next-generation industrial tools.

Solid-state metallurgy has unlocked entirely new classes of alloys that were previously difficult or impossible to produce through melting-based routes.

HEAs are composed of five or more principal elements in near-equal ratios. They exhibit remarkable combinations of strength, ductility, and thermal stability. Solid-state processing allows precise control over microstructures, enhancing their mechanical and corrosion properties.

By avoiding melting and solidification, solid-state techniques retain nanoscale grain structures, leading to extremely strong yet ductile metals.

These alloys find use in high-performance turbines, nuclear reactors, and lightweight armor.

Combining ceramics or fibers within metallic matrices improves stiffness, wear resistance, and heat tolerance. Solid-state processes enable uniform distribution of reinforcements, critical for structural integrity.

Solid-state metallurgy supports the creation of aluminum-lithium, titanium-aluminum, and magnesium-based alloys that meet strict weight and performance targets.

These materials are pivotal for electric vehicles and aircraft looking to improve fuel efficiency and range.

One of the most compelling advantages of solid-state metallurgy is its sustainability profile.

Since metals are never melted, energy consumption is significantly lower — often by 30–60% compared to conventional casting or forging. This translates into reduced greenhouse gas emissions and operating costs.

Furthermore, powder and additive methods minimize material waste, aligning with the global shift toward a circular manufacturing economy.

By reclaiming scrap metal powders and reusing feedstock efficiently, manufacturers can reduce resource dependency while producing superior alloys.

Solid-state metallurgy is already transforming multiple industries:

High-performance titanium and nickel alloys for turbine blades, heat exchangers, and fuselage components are now routinely processed via solid-state routes. The resulting parts are lighter, fatigue-resistant, and safer for extreme environments.

Lightweight aluminum and magnesium alloys processed through friction stir welding and powder metallurgy are enhancing vehicle performance and efficiency.

Armor plating and projectile materials benefit from fine microstructures and defect-free bonding, ensuring durability and ballistic resistance.

Solid-state diffusion and sintering techniques are producing radiation-resistant alloys and corrosion-proof materials for reactors, pipelines, and offshore structures.

Solid-state bonding enables precise micro-joining in semiconductors and thermal management systems, improving reliability and conductivity.

Solid-state metallurgy is evolving hand-in-hand with digital innovation. AI and machine learning are now used to predict alloy performance, optimize process parameters, and design microstructures.

Digital twins of manufacturing systems simulate every stage of the process, reducing experimentation and ensuring consistent quality.

AI-assisted modeling allows engineers to predict diffusion rates, phase transformations, and final mechanical properties — effectively bringing computational metallurgy into real-time industrial use.

This digital integration is ushering in the era of smart manufacturing, where solid-state processes adapt automatically for precision, speed, and sustainability.

While the advantages are clear, solid-state metallurgy still faces technical challenges that researchers are working to overcome:

Scalability: Some processes are limited to small parts or laboratory scales.

Tool Wear and Cost: High pressures and friction can degrade tools in processes like FSW.

Uniformity: Achieving consistent properties across large components requires precise temperature and pressure control.

Process Complexity: Each alloy behaves differently under solid-state conditions, demanding extensive testing.

Current research focuses on hybrid approaches that combine multiple solid-state techniques — for example, using spark plasma sintering followed by friction stir processing to enhance mechanical properties.

In addition, nanotechnology and additive solid-state layering are paving the way for next-generation alloy architectures with unprecedented precision.

Looking ahead, solid-state metallurgy is expected to revolutionize how metals are designed and produced.

In the coming decade, we can expect:

Full-scale industrial adoption in aerospace and EV sectors.

Smart, AI-controlled solid-state systems that autonomously optimize production.

New superalloys with nanoscale precision and self-healing capabilities.

Closed-loop recycling systems that reuse metal powders indefinitely.

Integration with 3D printing for sustainable, high-performance manufacturing.

As global industries shift toward carbon neutrality and digital transformation, solid-state metallurgy will serve as a bridge between material performance and environmental responsibility — defining the metals of the future.

Solid-state metallurgy enables the creation of advanced metal alloys without melting, using diffusion, pressure, and heat.

It produces stronger, cleaner, and more energy-efficient materials compared to conventional processes.

Key methods include powder metallurgy, diffusion bonding, friction stir welding, and spark plasma sintering.

Applications span aerospace, automotive, defense, energy, and electronics.

AI integration and additive manufacturing are accelerating innovation.

The approach supports sustainability through reduced energy use and waste recycling.

This article is for informational purposes only. Solid-state metallurgy and advanced alloy research are rapidly evolving fields. Performance metrics and industrial implementations may vary depending on process conditions, alloy types, and applications. Readers should consult material science experts and verified technical data before making engineering or investment decisions.

solid-state metallurgy, advanced alloys, powder metallurgy, diffusion bonding, additive metals, high-performance materials, metallurgy innovation, aerospace alloys, sustainable metals, nanostructured metals

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi