Post by : Amit

A week that puts composites in the spotlight

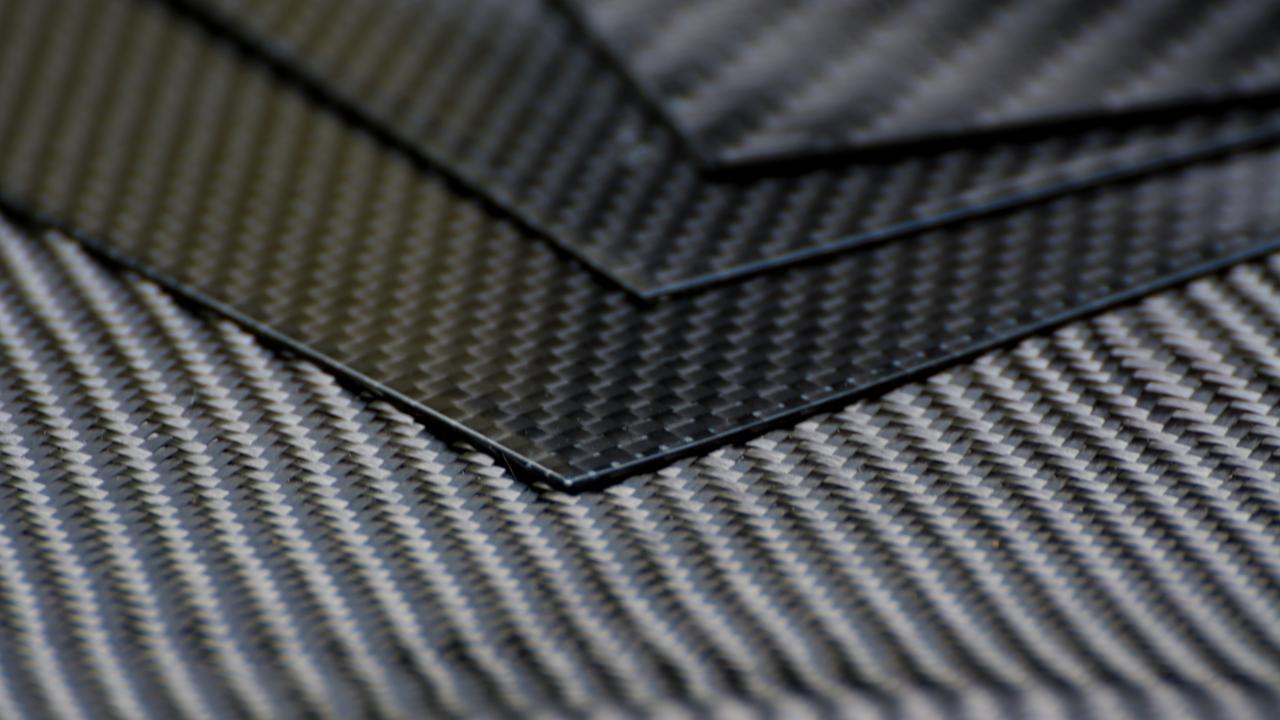

National Composites Week 2025 has arrived with a powerful message: advanced composites are no longer niche materials reserved for aerospace prototypes or high-end sports cars. They are rapidly becoming central to how we build, move, and connect in a world driven by sustainable mobility and efficiency. From aircraft fuselages to railway interiors, from electric vehicle platforms to urban mobility systems, lightweight materials are shaping the transport future.

The week-long celebration, coordinated by the American Composites Manufacturers Association (ACMA) and partner organizations, has taken on a global character this year, with events and case studies pouring in from Europe, Asia, and North America. What was once a specialist trade initiative now resonates across the broader transportation ecosystem, where composite adoption is often the difference between stagnation and innovation.

Transportation at a crossroads

The timing of this year’s National Composites Week could not be more symbolic. Aviation, shipping, rail, and automotive sectors all find themselves in a crucial transition. On one side are pressing climate targets, regulatory demands, and the rising costs of traditional materials. On the other is a technological wave of materials science, manufacturing automation, and circular design principles.

Advanced composites stand squarely at the intersection of these pressures and possibilities. Unlike steel or aluminum, they offer a unique combination of lightness and strength, enabling transportation systems to move faster, consume less energy, and last longer. For industries where every kilogram saved translates into millions of dollars in fuel costs or battery efficiency, composites are no longer optional—they are strategic.

Aerospace leading the charge

Aerospace has long been the testing ground for composite breakthroughs, and 2025 underscores how far the sector has come. Boeing, Airbus, and emerging manufacturers are increasingly dependent on composite fuselages, wings, and structural elements. The Boeing 787 Dreamliner and Airbus A350 are already known for their extensive use of lightweight materials, but the next generation of aircraft is expected to push beyond 50% composite content by weight.

This shift is not just about efficiency but also resilience. Composite structures allow more aerodynamic designs, reduce fatigue cracks compared to metals, and extend service life. As airlines grapple with decarbonization mandates, every percentage of fuel savings matters. Hydrogen and electric aircraft concepts showcased this week point to even greater reliance on composites to accommodate pressurized tanks, high-voltage insulation, and lightweight frames.

Rail embracing modern materials

The rail industry, often seen as conservative in its adoption of new materials, is emerging as a surprising champion of composites. Europe has taken the lead, with interior designers and rolling stock manufacturers embracing fiber-reinforced plastics and other composites for seats, doors, and panels.

The reasons are clear: lighter trains consume less electricity, while durable interiors resist vandalism, wear, and fire risks. Siemens Mobility and Alstom have showcased new train cabins this year featuring composite partitions and ergonomic panels, a far cry from the heavy steel frames of past decades. In Asia, high-speed rail programs are investigating composite bogies and couplers that can reduce maintenance cycles and improve safety performance.

Automakers betting big on lightweighting

For the automotive world, composites are rapidly moving beyond exotic sports cars into mass-market electric vehicles. Tesla, BMW, and Toyota are experimenting with carbon-fiber-reinforced plastics for battery enclosures, roof structures, and crash-resistant side beams. Lightweight materials are becoming indispensable as EV manufacturers seek to offset the heavy burden of lithium-ion battery packs.

This week, industry panels highlighted how composite-intensive vehicles can achieve ranges that rival or surpass conventional petrol cars. More importantly, composites open design possibilities for modular interiors, connected dashboards, and futuristic urban shuttles. In a competitive industry where every gram matters, composites may well decide the winners of the electric transition.

Shipping and marine innovation

Shipping, often accused of being slow to innovate, is experiencing its own composite revolution. The need for sustainable mobility at sea is pushing shipbuilders toward lighter, corrosion-resistant hulls and hybrid propulsion systems. Norwegian shipyards have launched ferries with composite superstructures, allowing vessels to save weight and therefore energy, while still meeting stringent safety and fire standards.

At National Composites Week, several case studies highlighted offshore wind support vessels that use composite propeller blades and deck structures. These innovations reduce downtime in harsh environments and cut maintenance costs, all while improving energy efficiency. In an industry facing carbon caps and global regulations, lightweight materials offer not just efficiency but survival.

Manufacturing challenges and breakthroughs

While the promise of advanced composites is clear, the path to mainstream adoption is not without obstacles. High costs, complex repair procedures, and recycling challenges have historically slowed growth. However, this year’s National Composites Week has showcased major breakthroughs.

Automation in composite layup, resin infusion, and 3D printing is driving down costs. Digital twins and AI-powered inspection tools are making quality control faster and more reliable. Just as importantly, circular economy models are beginning to take shape, with pilot plants in Europe demonstrating how old aircraft composite panels can be recycled into raw material for new automotive or construction applications.

A sustainable mobility driver

The link between composites and sustainability is perhaps the most powerful narrative of 2025. Governments across the globe are pushing industries toward net-zero commitments, and composites are increasingly recognized as an enabler of sustainable mobility.

Lightweight materials directly reduce emissions by cutting energy consumption, whether in the form of jet fuel, electricity, or marine diesel. More subtly, composites extend the lifespan of vehicles, lowering the environmental burden of replacements and maintenance. In urban contexts, composites make possible the new generation of micromobility solutions—electric scooters, bikes, and pods that are light, durable, and recyclable.

Human stories behind the technology

Beyond the technical jargon and statistics, National Composites Week is also about the people shaping this revolution. Engineers, designers, and factory workers are finding new purpose in solving transportation challenges with creativity and innovation.

At one panel, a young materials scientist from Ohio described how her team used bio-based resins to create a lightweight bus floor that is not only stronger than steel but also derived from renewable feedstocks. In another case, a shipyard engineer explained how composite lifeboats are saving lives by staying afloat in extreme weather where traditional models would capsize. These stories bring to life the real-world impact of composites, reminding us that materials science is ultimately about human progress.

Policy and investment momentum

Government policy is also playing a decisive role. In the United States, the Department of Energy and the Federal Aviation Administration have both expanded grants for composite research, tying funding directly to decarbonization goals. The European Union, meanwhile, has made lightweight materials a pillar of its Horizon Europe program, investing billions into collaborative research that bridges academia and industry.

Private investment is not lagging behind. Venture capital is flowing into startups focused on composite recycling, automation, and novel fibers. Automakers are entering joint ventures with composite suppliers, securing their supply chains as demand accelerates. The sense is clear: composites are no longer experimental—they are strategic infrastructure for the 21st century.

Global competition intensifies

National Composites Week 2025 has also highlighted the geopolitical dimension of materials science. Asia, particularly China and Japan, is racing ahead in scaling carbon fiber production, while the U.S. and Europe remain leaders in aerospace-grade applications. Supply chain resilience has become a buzzword, as nations seek to avoid dependency on foreign sources of critical fibers and resins.

The competition is intense, but it is also collaborative. Industry leaders stress that global challenges such as climate change and urban congestion demand cooperation as much as competition. The cross-border panels this week, featuring executives from three continents, underscored that the future of composites will be built on both rivalry and partnership.

Future

As National Composites Week 2025 draws to a close, one message rings louder than ever: advanced composites are not a side story in transportation. They are the main act. The materials that once seemed exotic are now indispensable, offering the keys to lighter, faster, and greener mobility across every mode of transport.

For industries navigating the turbulence of technological disruption, composites offer a steady compass. They are materials of resilience, efficiency, and imagination. The stories told this week—of engineers rethinking aircraft wings, of rail operators saving power, of shipbuilders cutting emissions—are not isolated anecdotes. They are signals of a profound transformation already underway.

Transportation is not just about moving people and goods; it is about connecting societies, enabling economies, and safeguarding our planet’s future. Composites, with their unique blend of lightness, strength, and sustainability, are central to that mission.

As the week’s events remind us, the next time we step into a train, board an aircraft, or ride an electric scooter, chances are that advanced composites are quietly carrying us forward. And in that quiet strength lies a revolution in motion—one that is redefining what mobility means in the 21st century.

Advanced composites, Lightweight materials, Sustainable mobility

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi