Post by : Amit

A Growing Web Beneath the Waves

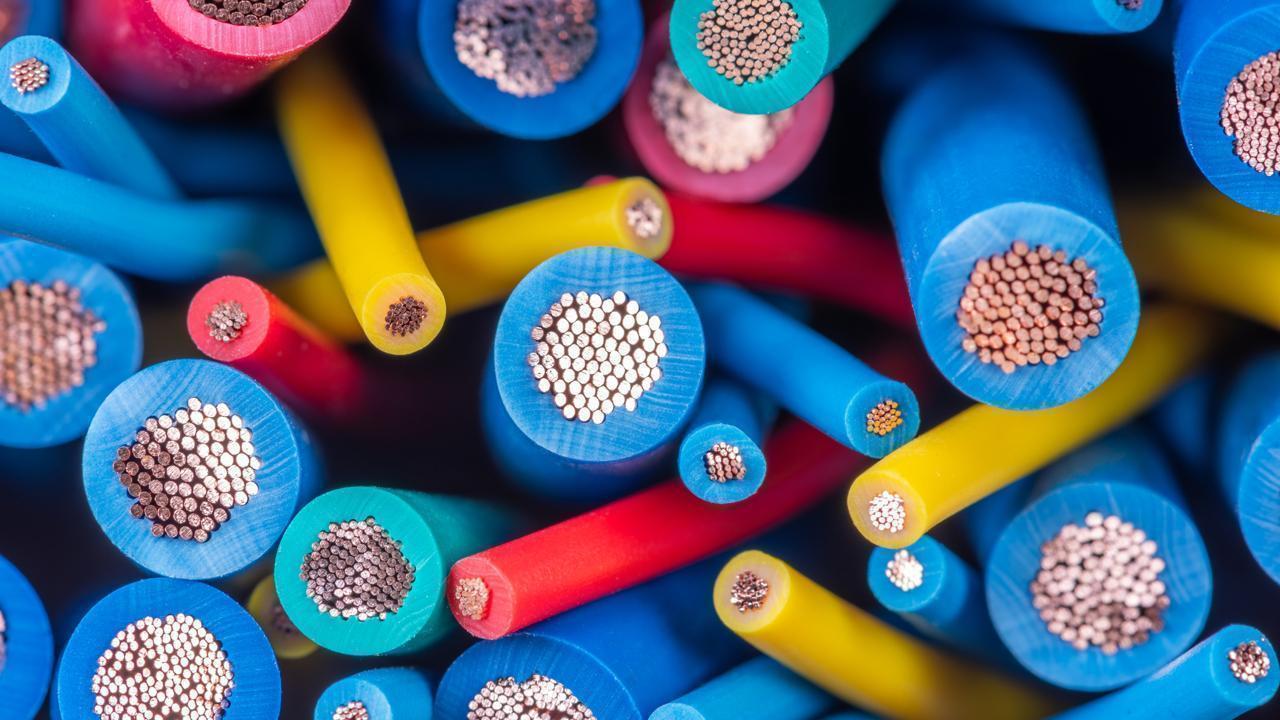

The global marine cabling and connectors sector is riding a wave of unprecedented demand, driven by the convergence of smart shipping technology, renewable offshore power, and the intensifying need for high-speed, high-reliability communications across oceans. From transoceanic data routes to the intricate electrical and fiber networks aboard the latest autonomous ships, the market’s backbone—literally—remains its advanced cabling infrastructure.

In 2025, industry analysts estimate the marine cabling market to be worth more than $15.6 billion, with growth projections exceeding 6% annually through 2030. The demand isn’t just for more cables—it’s for smarter, tougher, and more adaptable ones.

Offshore Wind and the Rise of Dynamic Cables

The surge in offshore wind farm development has been a major catalyst. In Europe alone, more than 30 new offshore wind projects are slated for completion by 2028, each requiring kilometers of subsea power cables and specialized connectors that can withstand punishing ocean conditions.

Dynamic cables—engineered to flex with tidal motion and platform movement—have become a focal point of innovation. Companies like Nexans and Prysmian are deploying hybrid cables capable of carrying both power and data to offshore substations, enabling more responsive grid management. This dual capability has drawn the attention of energy operators seeking cost efficiencies and better system monitoring.

Smart Ships Need Smarter Wiring

While much attention is given to ship propulsion and navigation systems, experts note that the wiring and connector networks on board are equally critical.

Modern vessels, particularly autonomous and semi-autonomous ships, are equipped with hundreds of sensors feeding real-time operational data into onboard AI systems. This data must move through ruggedized cabling systems designed to resist saltwater corrosion, electromagnetic interference, and mechanical wear from vibration.

Marine-grade fiber optics are now being installed alongside traditional power cabling, offering ultra-low latency data transfer between shipboard systems. Shipbuilders are also increasingly using modular cabling harnesses to simplify maintenance, reduce downtime, and allow faster technology upgrades—a necessity in an era when onboard systems can become obsolete within five years.

Deep-Sea Data Highways

Beyond shipboard needs, a parallel boom is unfolding under the seabed. Global data consumption—projected to triple between 2025 and 2030—is pushing telecom giants to lay thousands of kilometers of new subsea internet cables.

Marine cable layers are working on high-capacity transoceanic lines connecting emerging markets in Africa and Southeast Asia to global data hubs in Europe and North America. These new cables are increasingly built with advanced repeater technology, drawing power from embedded copper conductors while amplifying optical signals every 50–80 km.

Connectors, too, have evolved—using hermetically sealed, pressure-resistant designs that can be mated or unmated underwater by remotely operated vehicles (ROVs). This allows for quicker repairs and upgrades without recovering the entire cable section—a breakthrough that can save millions in downtime costs.

Sustainability and Circular Design Pressures

In an industry that traditionally focuses on ruggedness above all else, sustainability has become a defining challenge. Marine cable manufacturers are being pushed by regulators and customers to adopt circular design principles, including recyclable sheath materials and environmentally safe insulation compounds.

A recent project in Norway has successfully trialed biodegradable subsea cable coatings, which maintain structural integrity for over 20 years before naturally degrading if left in situ. The concept could drastically reduce the environmental footprint of decommissioned offshore assets.

Some shipyards are also implementing "cable mapping" during vessel construction, allowing for easier recovery and recycling of wiring when ships reach the end of their service lives.

Naval Applications Demand Absolute Reliability

Naval and coast guard fleets present an even more stringent set of requirements. Here, cables and connectors must operate flawlessly in high-vibration, high-electromagnetic-interference environments—often while carrying mission-critical communications or powering weapons systems.

Recent NATO trials have tested new electromagnetic shielding for marine cables, reducing susceptibility to jamming or detection. This technology is now being considered for integration into the next generation of patrol vessels and submarines.

Industry Consolidation and Investment

The competitive landscape is shifting. Mergers and acquisitions have accelerated as major cabling firms seek to integrate vertically—controlling design, manufacturing, installation, and maintenance under one corporate umbrella.

In early 2025, Denmark’s NKT acquired a majority stake in a specialist underwater connector company, aiming to bolster its share in offshore defense and renewable markets. Meanwhile, Asian manufacturers are scaling up production facilities in anticipation of rising demand from both domestic shipbuilding booms and cross-border subsea telecom projects.

Venture capital has also flowed into marine cabling startups, particularly those developing AI-driven cable monitoring systems. These platforms use real-time sensing data to predict wear, detect faults, and schedule preventative maintenance long before failures occur.

Geopolitics and Repair Logistics

Despite the bullish market outlook, industry insiders warn of looming challenges. Geopolitical tensions have made certain subsea routes riskier to deploy and maintain. In contested maritime zones, cable-laying ships may face delays or even harassment, increasing project costs and uncertainty.

Repair logistics remain another hurdle. Subsea cable faults, often caused by fishing activity or anchor drags, can take weeks to locate and fix. The growing complexity of hybrid cables—carrying both data and power—means repair crews must be trained in multiple engineering disciplines, adding to operational costs.

The Road (and Sea) Ahead

The coming decade will see marine cabling and connectors play an increasingly central role in both maritime commerce and global communications. As ships evolve into floating data centers, offshore renewables expand, and subsea internet backbones multiply, the invisible infrastructure beneath the waves will be the lifeline connecting every part of the maritime ecosystem.

For the companies leading this charge, success will hinge on their ability to balance rugged engineering with smart technology and environmental responsibility. The cables may be hidden from view, but their impact on the future of the seas will be impossible to miss.

Subsea cabling, Subsea cables

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi