Post by : Amit

Toyota Bets Big on U.S. EV Future with $1.9 Billion Battery Plant Expansion

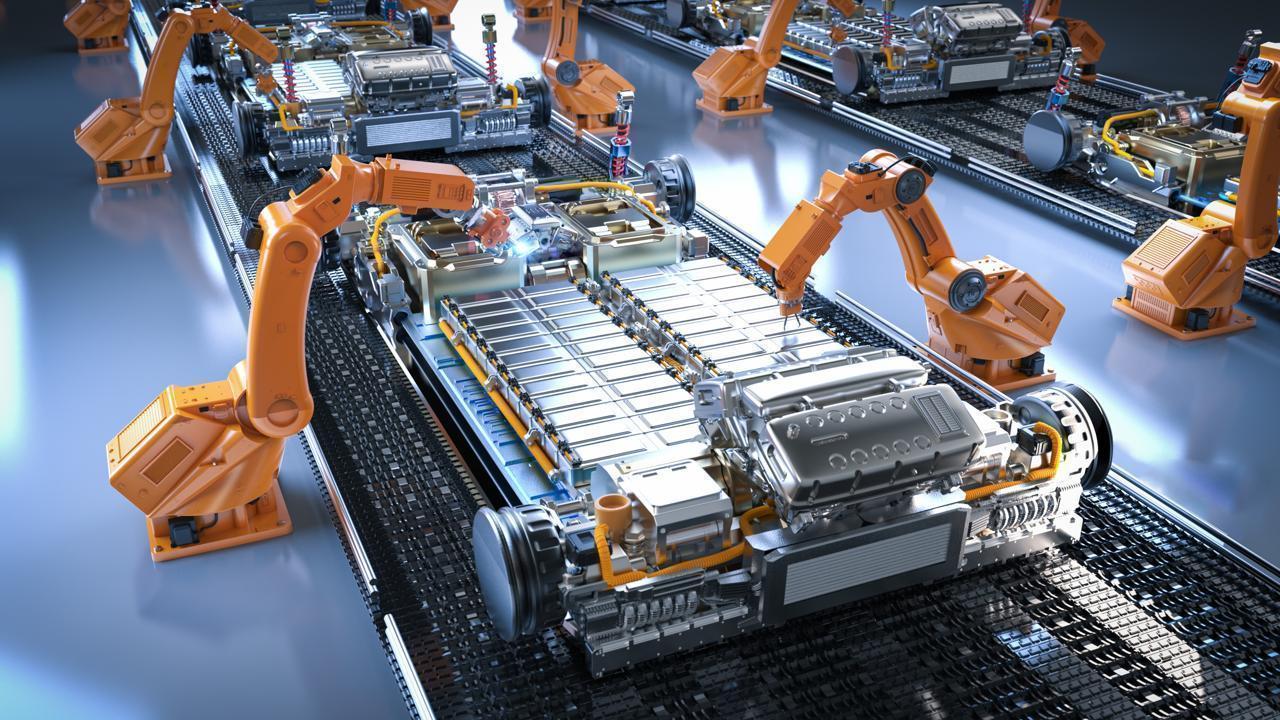

Toyota Motor Corporation has announced an additional $1.9 billion investment to expand its EV battery manufacturing facility in North Carolina, USA. This brings Toyota’s total commitment to the Liberty, North Carolina site to over $13.9 billion since the project’s inception in 2021, making it one of the largest battery-focused investments in U.S. automotive history.

The expansion comes as part of Toyota’s broader strategy to rapidly scale its North American EV and hybrid production capabilities, signaling a decisive pivot from its traditionally conservative stance on full battery electric vehicles. Once operational, the Liberty site is expected to be a key hub for powering Toyota and Lexus EVs for the North American market, with production slated to begin as early as 2025.

This isn’t just another auto plant—it’s a signal flare in the intensifying global race to dominate the EV battery supply chain, and a vital anchor point in the U.S. government’s mission to localize clean energy production and secure critical infrastructure from geopolitical disruptions.

The Strategic Importance of the Liberty, NC Site

Situated in Randolph County, the Liberty facility was first announced in 2021 as a joint venture between Toyota and Toyota Tsusho. Over time, the site’s mission has expanded dramatically, evolving from a modest battery cell plant to a massive industrial complex with multiple production lines for lithium-ion and solid-state battery technologies.

Toyota’s new $1.9 billion infusion will fund the construction of additional battery assembly lines, as well as upgrade existing infrastructure to support a wider range of battery chemistries. This includes high-capacity packs for fully electric vehicles and advanced nickel-metal hydride packs for Toyota’s next-gen hybrid models.

Once complete, the facility will house at least ten battery production lines, creating over 5,000 high-skill jobs in the region. According to Toyota, the plant will have an annual output capacity to support between 1.2 and 1.5 million electrified vehicles.

Liberty’s location is no accident. North Carolina offers access to key logistics corridors, skilled labor, and a growing ecosystem of EV-focused startups and battery materials suppliers. Its proximity to Toyota’s existing assembly plants in Kentucky and Mississippi makes it a natural fit for regional supply optimization.

From Hybrids to BEVs: A New Chapter for Toyota

Toyota’s leadership in hybrid technology is uncontested. The Prius, introduced in the late 1990s, remains a global icon of fuel efficiency. But in the battery electric vehicle (BEV) arena, Toyota has been criticized for lagging behind rivals like Tesla, Hyundai, and Ford in embracing all-electric platforms.

That appears to be changing — and rapidly.

In June 2023, Toyota announced a radical restructuring of its EV division, appointing a new leadership team with mandates for aggressive electrification. The company has since committed to launching ten new battery electric models globally by 2026 and aims to sell 3.5 million EVs annually by 2030.

The expanded North Carolina battery plant is central to that plan. By localizing battery production, Toyota is not only reducing its reliance on overseas suppliers but also aligning itself with the growing demand for U.S.-made EVs, especially under the incentives framework of the Inflation Reduction Act (IRA).

Batteries produced in Liberty will help Toyota vehicles qualify for federal EV tax credits — a critical factor for competing in the mass market as consumers become increasingly cost-conscious in the face of economic uncertainty.

A Crucial Win for U.S. Manufacturing Policy

Toyota’s decision is a major victory for the Biden administration’s industrial policy, which has prioritized EVs, renewable energy, and onshoring of critical technologies.

Under the IRA and the CHIPS and Science Act, billions of dollars in federal incentives have been unlocked for companies investing in U.S.-based manufacturing. Toyota, though historically cautious in lobbying or political alignment, is now strategically positioning itself to capitalize on this wave of public-private alignment.

Commerce Secretary Gina Raimondo praised the move, noting, “Toyota’s expansion in North Carolina reflects the success of our strategy to bring clean energy jobs back to American soil. This is not just about cars — it’s about industrial competitiveness.”

Local officials echoed this sentiment. North Carolina Governor Roy Cooper stated, “This investment is transformative. It puts North Carolina on the map not only as a manufacturing state, but as a leader in the global EV transition.”

Toyota is also collaborating with state and local economic development agencies to invest in STEM education, technical training programs, and local supplier development, ensuring the Liberty site becomes a self-sustaining industrial ecosystem.

Batteries at the Center of Supply Chain Resilience

Global battery supply chains remain fragile. From lithium mining in South America to cobalt extraction in the Democratic Republic of Congo, the materials used in EV batteries are geographically concentrated and fraught with environmental and ethical challenges.

By bringing battery production onshore, Toyota is aiming to hedge against these uncertainties. The Liberty facility will use a mix of imported and domestic raw materials initially, but Toyota has indicated plans to work with U.S.-based materials processors in the near future.

Negotiations are reportedly underway with domestic lithium producers in Nevada and North Carolina, as well as nickel refining partners in Canada. Toyota is also exploring closed-loop battery recycling systems to recover rare earth elements from end-of-life batteries.

By controlling more of the value chain, Toyota can better forecast costs, ensure compliance with ESG standards, and reduce geopolitical exposure. These capabilities will be essential as battery costs continue to be the most volatile component in EV pricing.

Jobs, Training, and Regional Growth

The economic implications of Toyota’s expansion are substantial. Over 5,000 new jobs are expected to be created, ranging from engineers and quality control experts to assembly line workers and logistics coordinators. Toyota is investing in partnerships with nearby universities, community colleges, and trade schools to ensure a robust talent pipeline.

The Liberty site is also expected to create thousands of indirect jobs across the region, including in construction, maintenance, transportation, and local supplier networks. Initial estimates from the North Carolina Department of Commerce suggest that for every direct job created at the facility, an additional 2.5 jobs will be generated in the wider economy.

Suppliers are already setting up shop near the facility, drawn by the long-term business opportunities a major OEM anchor tenant provides. Battery component companies, thermal management firms, and packaging suppliers are establishing local hubs, further deepening the site’s economic footprint.

Toyota’s investment is, in essence, turning a quiet stretch of North Carolina farmland into a strategic node in the global energy transition.

Toyota’s Broader U.S. EV Ambitions

The Liberty facility is part of a sweeping overhaul of Toyota’s North American manufacturing strategy. The company has already begun retooling plants in Kentucky, Indiana, and Alabama to accommodate electric and hybrid vehicle platforms.

In Georgetown, Kentucky — home to Toyota’s largest U.S. manufacturing site — plans are underway to begin producing a new all-electric SUV by 2025, with battery packs sourced directly from Liberty. Similarly, Toyota’s engine plant in Huntsville, Alabama is being upgraded to produce components compatible with hybrid powertrains.

These changes indicate a company-wide pivot toward electrification — and a recognition that the U.S. will be a critical battleground in the global EV race.

Toyota is also exploring charging infrastructure partnerships, vehicle-to-grid pilot programs, and advanced battery R&D projects in the U.S., further expanding its footprint in the clean mobility ecosystem.

Challenges and Questions

Despite the momentum, Toyota still faces considerable challenges.

First, the company must reconcile its continued commitment to hybrids with growing regulatory pressure in key markets to phase out internal combustion engines altogether. While hybrids remain popular and profitable, jurisdictions like California and the European Union are tightening rules that could marginalize hybrid models within the next decade.

Second, battery technology is evolving rapidly. While Toyota is investing in solid-state battery R&D, mass-market commercial viability is still years away. The Liberty site’s flexibility — its ability to support multiple chemistries — will be tested as the market moves toward higher-density, faster-charging alternatives.

Finally, there is the competitive threat. Tesla’s Gigafactories, GM’s Ultium Cells, and Ford’s BlueOval SK plants are all scaling at breakneck speed. Toyota’s legacy efficiency and reputation may not be enough to compete with newer entrants aggressively innovating in both hardware and software.

Yet, Toyota’s methodical approach — grounded in manufacturing excellence, strategic investment, and long-term planning — may prove to be its greatest strength as the EV era matures.

A Defining Moment for Toyota and U.S. Manufacturing

Toyota’s $1.9 billion expansion of its EV battery plant in North Carolina is more than just an industrial upgrade — it’s a declaration of intent. It signals that the world’s largest automaker is ready to compete seriously in the all-electric arena and that it is willing to align itself with the evolving energy and manufacturing priorities of its largest market.

In the broader context of shifting global supply chains, technological upheaval, and the climate imperative, this move places Toyota at the heart of the U.S. clean energy revolution. It also brings critical battery infrastructure closer to American consumers, enhancing energy security, economic resilience, and environmental accountability.

As the automotive world races toward a zero-emissions future, Toyota’s North Carolina expansion may very well be remembered as the moment it decided to lead — not follow — into the age of electrification.

Toyota, Ev Battery, Future Mobility

Advances in Aerospace Technology and Commercial Aviation Recovery

Insights into breakthrough aerospace technologies and commercial aviation’s recovery amid 2025 chall

Defense Modernization and Strategic Spending Trends

Explore key trends in global defense modernization and strategic military spending shaping 2025 secu

Tens of Thousands Protest in Serbia on Anniversary of Deadly Roof Collapse

Tens of thousands in Novi Sad mark a year since a deadly station roof collapse that killed 16, prote

Canada PM Carney Apologizes to Trump Over Controversial Reagan Anti-Tariff Ad

Canadian PM Mark Carney apologized to President Trump over an Ontario anti-tariff ad quoting Reagan,

The ad that stirred a hornets nest, and made Canadian PM Carney say sorry to Trump

Canadian PM Mark Carney apologizes to US President Trump after a tariff-related ad causes diplomatic

Bengaluru-Mumbai Superfast Train Approved After 30-Year Wait

Railways approves new superfast train connecting Bengaluru and Mumbai, ending a 30-year demand, easi